Adsorption of solvent vapors by activated carbon and inert gas regeneration may be used to recover VOC’s (Volatile Organic Compounds) in a form that can be reused. Low temperature condensation also offers the possibility of recovery of VOC’s in a pure form. NUCON International specializes in both types of VOC recovery.

Process Design Methods

A thermodynamically rigorous process simulator is used to calculate physical properties and vapor/liquid equilibrium. Carbon adsorption isotherms are developed in NUCON’s laboratories. Designs are validated by engineers with many years of experience in solvent recovery and carbon adsorption.

Carbon Adsorption with the Braysorb® System

Adsorption by activated carbon followed by hot gas regeneration and low temperature condensation is the optimum process for treating dilute VOC concentrations. Braysorb® systems can be designed to handle very large gas flows.

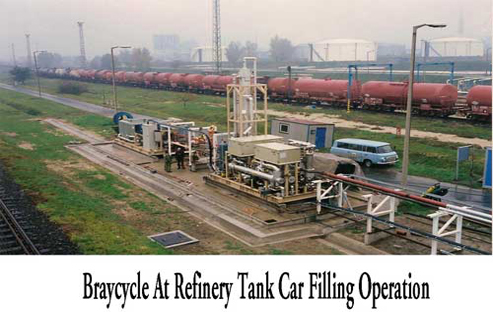

VOC Recovery by the Braycycle® System

In this system the gas stream is cooled to very low temperatures. The condensed solvent may be collected without introducing any additional impurities. The Braycycle® system is used when the VOC concentrations are relatively high.

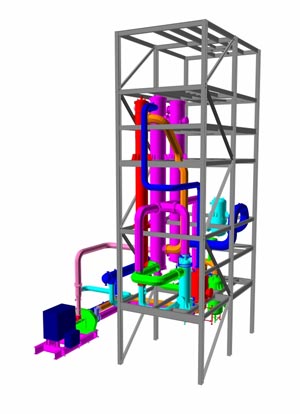

Scope of Supply

NUCON can provide a complete design including PFD, P&ID, mechanical arrangement, fabrication and 3D drawings and equipment specifications. Equipment procurement and piping fabrication is included and, for smaller systems, the solvent recovery unit can be supplied on a skid ready for connection to the plant process lines and utilities.

Modification and Upgrading of Existing systems.

For a number of reasons, solvent recovery equipment installed to perform a process or system control function may not be operating effectively. NUCON has the capability to assist you in troubleshooting and making improvements in the operation